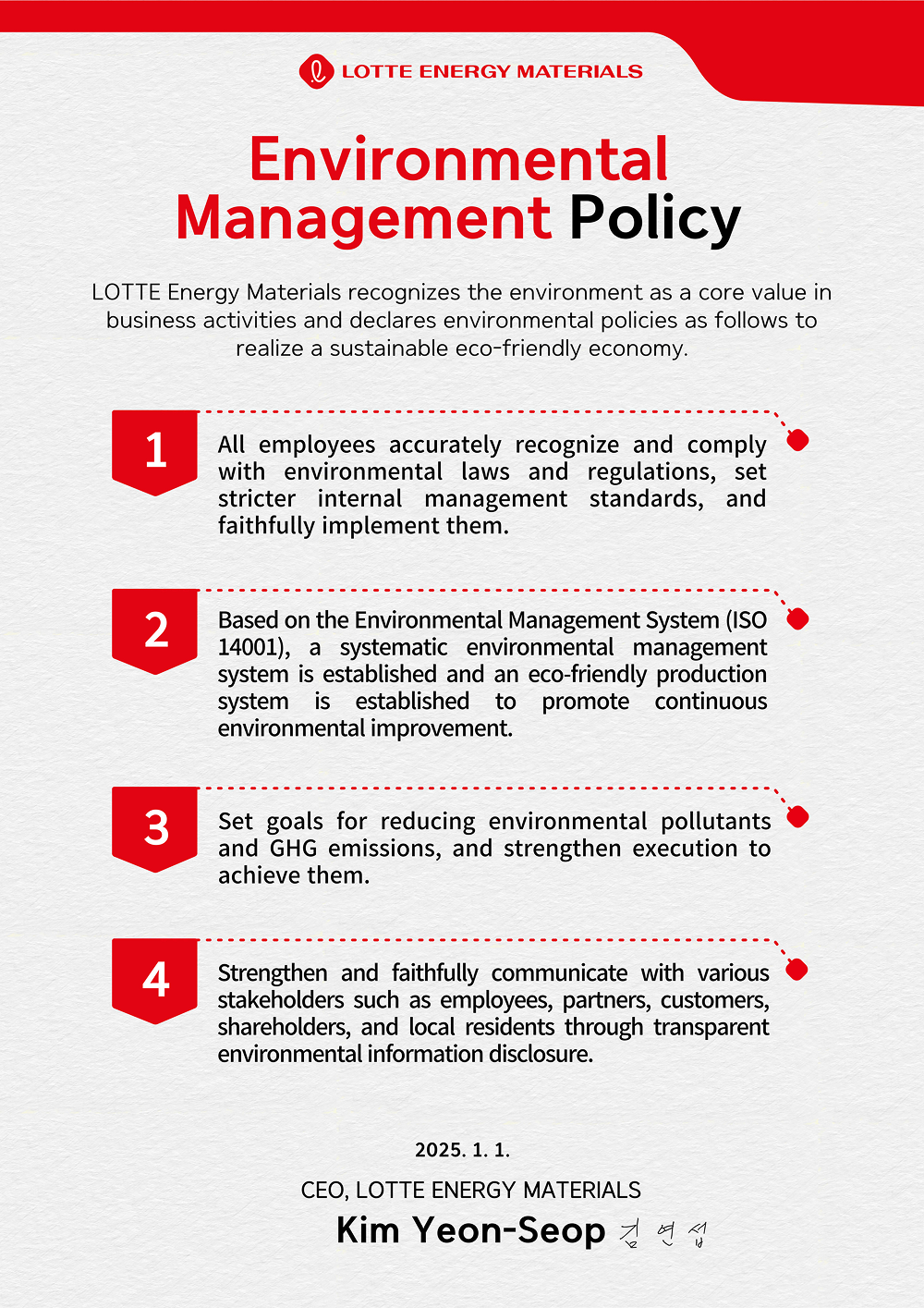

LOTTE ENERGY MATERIALS recognizes safety and

the environment as top management priorities and pursues sustainable development.

LOTTE ENERGY MATERIALS recognizes safety and the environment as top management priorities and pursues sustainable development.

-

Creating a safe and healthy workplaceCompliance with internal standards that are stronger than legal standards Establishment of a bottom-up approach safety and health management system Strengthening internal and external safety and health networks

Creating a safe and healthy workplaceCompliance with internal standards that are stronger than legal standards Establishment of a bottom-up approach safety and health management system Strengthening internal and external safety and health networks -

Eco-friendly companyCompliance with internal standards that are stronger than legal standards Minimizing greenhouse gas and pollutant emissions Establishment of internal and external eco-friendly partnerships

Eco-friendly companyCompliance with internal standards that are stronger than legal standards Minimizing greenhouse gas and pollutant emissions Establishment of internal and external eco-friendly partnerships

- Emergency response

training (Iksan Plant 1) - Emergency response

training (Iksan Plant 2) - Safety environment

monitoring group - Safety environment

contest - TPM

- Emergency Response

Education and Training

Emergency response training (Iksan Plant 1)

- Participants: All executives and employees

- Training cycle: Twice a year

LOTTE ENERGY MATERIALS Iksan Plant 1 conducts emergency response training twice a year to minimize damage to life and property

in the event of fire or chemical accidents (Including joint fire drills with local fire departments).

Emergency response training (Iksan Plant 2)

- Participants: All executives and employees

- Training cycle: Twice a year

LOTTE ENERGY MATERIALS Iksan Plant 2 conducts emergency response training twice a year to minimize damage to life and property

in the event of fire or chemical accidents (Including joint fire drills with local fire departments).

Safety environment monitoring group

- Participants: Plant manager, safety and environment department, and chief of each process

- Training cycle: Once a Week

LOTTE ENERGY MATERIALS operates the safety environment monitoring group every week to proactively discover and improve over potential risk factors.

Safety environment contest

- Participants: All executives and employee

- Training cycle: Once a year

LOTTE ENERGY MATERIALS holds a safety environment contest every year to raise awareness of the safety environment among all executives and employees.

TPM (Total Productive Maintenance)

- Participants: All executives and employees, professional consulting company

- Training cycle: On a regular basis

At LOTTE ENERGY MATERIALS, all executives and employees participate in TPM activities on a regular basis to create a healthy and safe workplace.

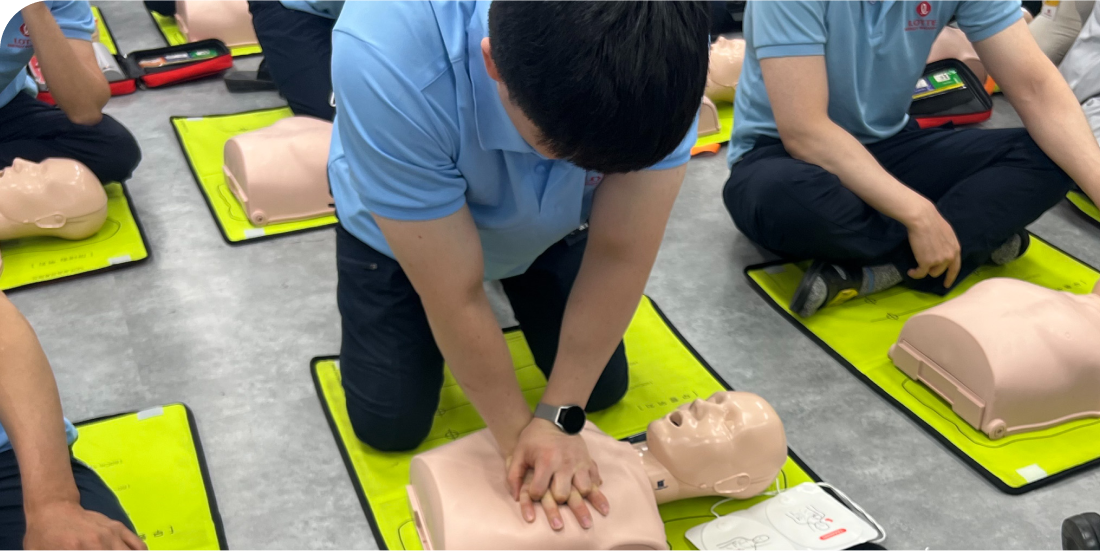

Emergency Response Education and Training

- Participants : All executives and employees

- Training cycle : Once a year

LOTTE Energy Materials Iksan Plant 1 conducts a practical emergency response course once a year in collaboration with local institutions to improve the emergency response capabilities of its workers.

Emergency response training (Iksan Plant 1)

- Participants : All executives and employees

- Training cycle : Twice a year

LOTTE ENERGY MATERIALS Iksan Plant 1 conducts emergency response training twice a year to minimize damage to life and property in the event of fire or chemical accidents (Including joint fire drills with local fire departments).

Emergency response training (Iksan Plant 2)

- Participants : All executives and employees

- Training cycle : Twice a year

LOTTE ENERGY MATERIALS Iksan Plant 2 conducts emergency response training twice a year to minimize damage to life and property in the event of fire or chemical accidents (Including joint fire drills with local fire departments).

Safety environment monitoring group

- Participants : Plant manager, safety and environment department, and chief of each process

- Training cycle : Once a Week

LOTTE ENERGY MATERIALS operates the safety environment monitoring group every week

to proactively discover and improve over potential risk factors.

Safety environment contest

- Participants : All executives and employees

- Training cycle : Once a year

LOTTE ENERGY MATERIALS holds a safety environment

contest every year to raise awareness of the

safety environment among all executives and employees.

TPM (Total Productive Maintenance)

- Participants : All executives and employees, professional consulting company

- Training cycle : On a regular basis

At LOTTE ENERGY MATERIALS, all executives and employees participate in TPM activities on a regular basis to create a healthy and safe workplace.

Emergency Response Education and Training

- Participants : All executives and employees

- Training cycle : Once a year

LOTTE Energy Materials Iksan Plant 1 conducts a practical emergency response course once a year in collaboration with local institutions to improve the emergency response capabilities of its workers.