Elecfoil for Secondary Battery Elecfoil(Electrodeposited copper foil) for secondary battery is an essential component utilized as the anode current collector

in lithium-ion battery, which are integral to electric vehicle (EV) battery technology. LOTTE ENERGY MATERIALS is at the forefront

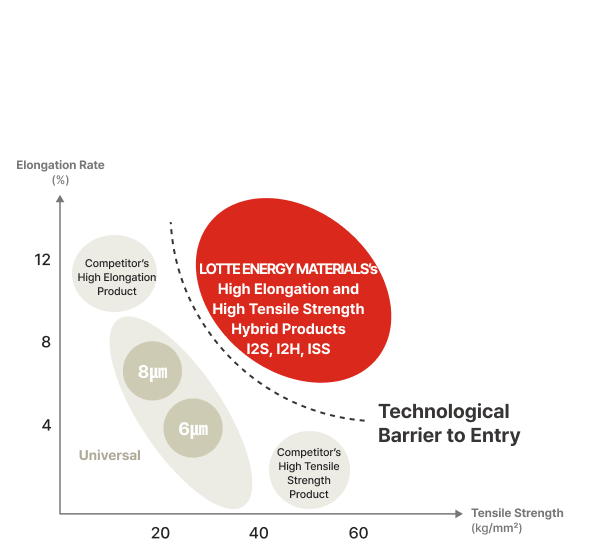

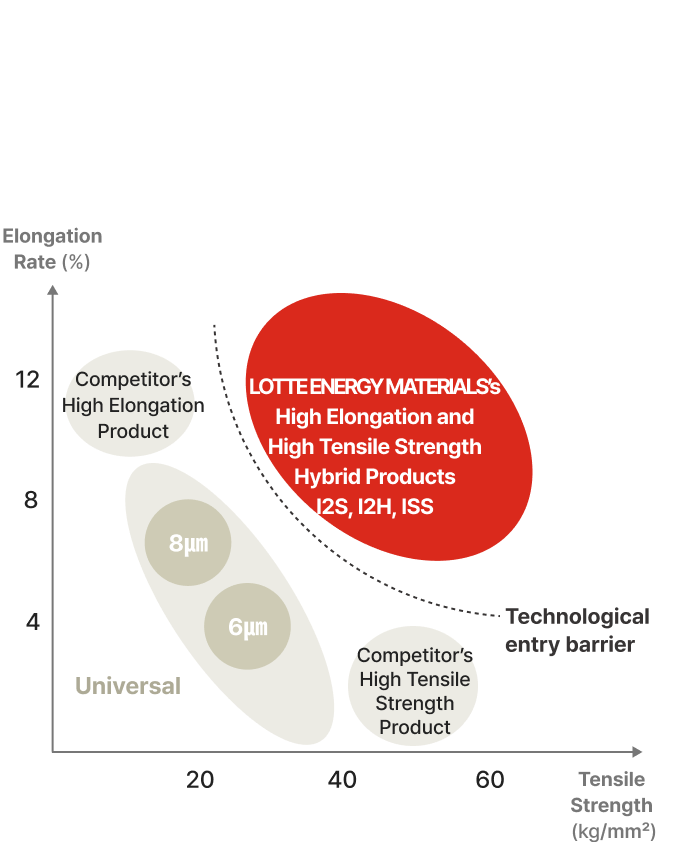

of innovation and production, focusing on High-End Elecfoil engineered to meet the stringent demands for increased strength and elongation.

These properties are crucial for enhancing the driving range, ensuring the safety of charge-discharge cycles, and boosting the energy density of EVs. Also, we are pioneering the industry with unique combination of ultra-thinness, high strength, and high elongation properties and a portfolio of patents. Elecfoil(Electrodeposited copper foil) for secondary battery is an essential component utilized as the anode current collector in lithium-ion battery, which are integral to electric vehicle (EV) battery technology.

LOTTE ENERGY MATERIALS is at the forefront of innovation and production, focusing on High-End Elecfoil engineered to meet the stringent demands for increased strength and elongation.

These properties are crucial for enhancing the driving range, ensuring the safety of charge-discharge cycles, and boosting the energy density of EVs.

Also, we are pioneering the industry with unique combination of ultra-thinness, high strength, and high elongation properties and a portfolio of patents.

-

Ultra-Thin 4㎛

-

High Strength 70kgf/㎟

-

High Elongation 12%

+ High elongation Hybrid Elecfoil Products

Batteries with Customer-Customized

Innovative Technology

Ultra-thin + High strength + High elongation

Hybrid Elecfoil Products

Establishment of Technological Entry Barriers

by Holding Patents for Hybrid Elecfoil Products

- 1 i/P : Shape of the production process, such as the winding of copper foil

- 2 S/T/E : The Core Technology contained in our

Elecfoil (i ~ P) - 3 Hi/P : High Technology, Productivity

2025 to strengthen promotion efforts and differentiate

its Hybrid High-End products.

HiSTEP is a leading brand featuring high‑strength,

high‑elongation Hybrid High-End copper foil with advanced

performance and premium material solutions.

The brand focuses on maintaining an optimal balance between

tensile strength and elongation while ensuring a stable and

reliable thin-film process.

Improve battery

electrode productivityImproved battery life

Improved battery

performanceReduce thickness of battery

anode current collector

We are the only company in the industry that possesses hybrid copper foil products that simultaneously satisfy Ultra-thin, High-strength, and High-elongation

requirements, and we prioritize the production of customer-customized products.

* Based on a thickness of 8㎛ for tensile strength and elongation

| Classification | High strength | High elongation | Hybrid High-End | ||||||

|---|---|---|---|---|---|---|---|---|---|

| L2S | ST5 | ST6 | L2H | L2SH | ST5H | ST6H | |||

| Room temperature |

Tensile strength |

kgf/mm² | 40~49 | 50~59 | 60~69 | 30~38 | 40~49 | 50~59 | 60~69 |

| Elongation | % | ≥8 | ≥7 | ≥4 | ≥12 | ≥11 | ≥10 | ≥6 | |

| High temperature |

Tensile strength |

kgf/mm² | 37~45 | 45~55 | ≥50 | 27~35 | 37~45 | 45~55 | ≥50 |

| Elongation | % | ≥8 | ≥7 | ≥4 | ≥13 | ≥11 | ≥10 | ≥6 | |

| Product thickness | ≥4µm | ≥4µm | ≥5µm | ≥5µm | ≥4µm | ≥4µm | ≥5µm | ||

| Classification | L2B | ||

|---|---|---|---|

| Product thickness | ㎛ | 8㎛ | |

| Room temperature |

Tensile strength |

kgf/mm² | 30~38 |

| Elongation | % | ≥6 | |

| High temperature |

Tensile strength |

kgf/mm² | 27~35 |

| Elongation | % | ≥7 | |

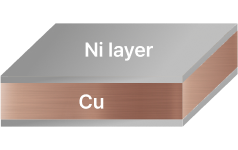

| Classification | for Solid-state batteries | ||

|---|---|---|---|

| LDN | |||

| Structure | Ni plated Cu foil |  |

|

| Elecfoil- thickness |

㎛ |

8~10 |

|

| Ni-thickness | ㎛ |

0.1~1.0 |

|

| Tensile strength |

kgf/㎟ |

40~55 |

|

| Features |

|

||

* Based on a thickness of 8㎛ for tensile strength and elongation

| Classification | High strength | High elongation | Hybrid High-End | ||||||

|---|---|---|---|---|---|---|---|---|---|

| L2S | ST5 | ST6 | L2H | L2SH | ST5H | ST6H | |||

| Room temperature |

Tensile strength |

kgf/mm² | 40~49 | 50~59 | 60~69 | 30~38 | 40~49 | 50~59 | 60~69 |

| Elongation | % | ≥8 | ≥7 | ≥4 | ≥12 | ≥11 | ≥10 | ≥6 | |

| High temperature |

Tensile strength |

kgf/mm² | 37~45 | 45~55 | ≥50 | 27~35 | 37~45 | 45~55 | ≥50 |

| Elongation | % | ≥8 | ≥7 | ≥4 | ≥13 | ≥11 | ≥10 | ≥6 | |

| Product thickness | ≥4µm | ≥4µm | ≥5µm | ≥5µm | ≥4µm | ≥4µm | ≥5µm | ||

| Classification | L2B | ||

|---|---|---|---|

| Product thickness | ㎛ | 8㎛ | |

| Room temperature |

Tensile strength |

kgf/mm² | 30~38 |

| Elongation | % | ≥6 | |

| High temperature |

Tensile strength |

kgf/mm² | 27~35 |

| Elongation | % | ≥7 | |

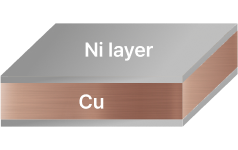

| Classification | for Solid-state batteries | ||

|---|---|---|---|

| LDN | |||

| Structure | Ni plated Cu foil |  |

|

| Elecfoil- thickness |

㎛ |

8~10 |

|

| Ni-thickness | ㎛ |

0.1~1.0 |

|

| Tensile strength |

kgf/㎟ |

40~55 |

|

| Features |

|

||